Precision Processing Technology for Copper Stamping Parts

Copper stamping parts are widely used in modern manufacturing, especially in the electronics, automotive, and communications industries. Due to the excellent electrical and thermal conductivity of copper materials, copper stamping parts hold an important position in these fields. To ensure high precision and quality of copper stamping parts, precision machining technology plays a crucial role in the production process. This article will delve into the precision machining technology of copper stamping parts and their applications.

Precision Requirements of Copper Stamping Parts

Copper stamping parts are typically used in applications that require high precision and complex structures. Therefore, the manufacturing of copper stamping parts must meet strict accuracy requirements, especially in terms of dimensional tolerance, shape accuracy, and surface finish. Precision machining technology can effectively improve the production precision of copper stamping parts, ensuring their good performance and stability during use.

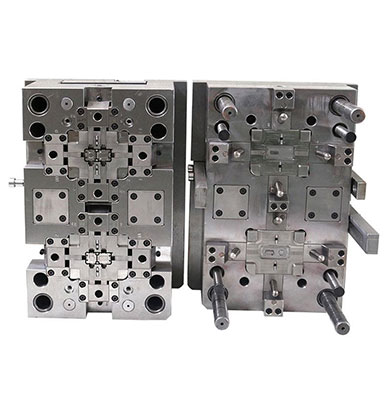

High-Precision Mold Design

The first step of precision machining is mold design. The mold is the core tool in the production of copper stamping parts, and the design of the mold directly affects the final product's precision and quality. In the manufacturing process of copper stamping parts, using high-precision molds can reduce material waste and improve production efficiency. The choice of mold materials, control of machining accuracy, and mold durability are key factors that affect the quality of copper stamping parts. Through computer-aided design and computer-aided manufacturing technology, mold designs can be more precise, ensuring the high-precision production of copper stamping parts.

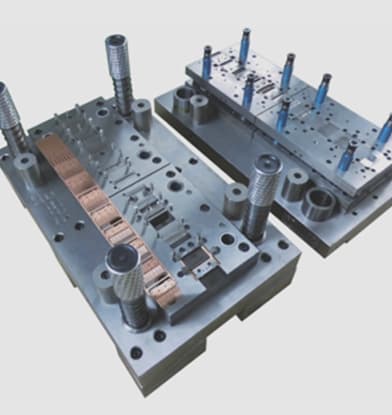

Precision Stamping Technology

Precision stamping technology is the core process in the manufacturing of copper stamping parts. Compared to traditional stamping processes, precision stamping technology can produce complex-shaped copper stamping parts under higher precision requirements. Precision stamping equipment features higher stamping accuracy and more stable operating performance, ensuring that the dimensional tolerance of copper stamping parts remains within strict ranges and reducing deformation and cracking issues during machining.

During the precision stamping process, rational pressure and speed control can effectively manage material deformation, preventing material loss and product defects caused by excessive stamping. This precision stamping technology is commonly used for producing microelectronic components, precision connectors, and other high-demand copper stamping parts.

Advantages of Precision Machining Technology

Precision machining technology for copper stamping parts offers the following advantages.

High Precision

Through high-precision molds and precision stamping processes, the dimensional tolerance and shape accuracy of copper stamping parts are greatly improved, meeting the application needs for high precision.

Increased Efficiency

The combination of automated control technology and precision machining equipment improves production efficiency and shortens delivery times.

Stability

Precision machining technology ensures that copper stamping parts maintain high performance and stability over long-term use, reducing failures due to size non-conformity.

Material Savings

Precise mold design and efficient stamping processes reduce material waste, lowering production costs.

Copper stamping parts, as an important component of modern manufacturing, have their quality and reliability determined by precision machining technology. Through high-precision mold design, precision stamping technology, automated control, and surface treatment processes, copper stamping parts can meet increasingly complex industrial demands. If you are looking for a high-quality copper stamping parts manufacturer, Orienson offers excellent precision machining technology and custom services, providing you with high-precision and highly stable copper stamping solutions.

English

English