Definition and Advantages of OEM Metal Stamping Parts

In modern manufacturing, OEM metal stamping parts are an important component manufacturing method widely used in various industries such as automotive, electronics, and home appliances. With efficient production processes and superior performance characteristics, they have become the preferred choice for many companies. This article will provide a detailed analysis of the relevant content of OEM metal stamping parts from the perspectives of definition and advantages.

Definition of OEM Metal Stamping Parts

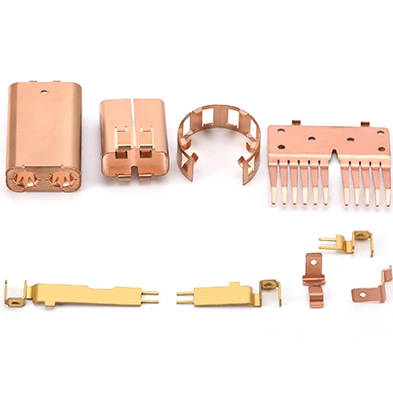

OEM metal stamping parts refer to components produced by Original Equipment Manufacturers (OEM) using metal stamping processes based on customer needs. Through precise molds and mechanical equipment, metal sheets are shaped into various forms and structures under pressure. These stamped parts typically have high precision and can meet the stringent size and shape requirements of specific industries. The application fields of OEM metal stamping parts are very wide, covering industries such as automotive, electronics, machinery, and aviation.

OEM Metal Stamping Parts: High Precision and Consistency

A significant advantage of OEM metal stamping parts is their high precision and consistency. During the stamping process, the use of precise mold design and efficient stamping equipment ensures that each component's dimensions and shapes exactly match the design requirements. Whether in mass production or small-batch customization, OEM metal stamping parts can maintain consistent quality, meeting the high precision demands of applications such as automotive parts and electronic accessories. This high precision and consistency make OEM metal stamping parts play an important role in many fields.

OEM Metal Stamping Parts: Reduced Production Costs

OEM metal stamping parts have significant cost advantages. Compared with other traditional processing methods, the metal stamping process has notable cost efficiency in mass production. The stamping process not only minimizes material waste but also enhances production efficiency through automation, reducing labor costs. Moreover, the production cycle of OEM metal stamping parts is relatively short, enabling companies to respond to market demands more quickly, further improving cost-effectiveness.

OEM Metal Stamping Parts: Diverse Material Choices

OEM metal stamping parts are suitable for various metal materials such as steel, aluminum, copper, and alloys. Different materials endow stamped parts with different performance characteristics to meet the needs of different industries and applications. For instance, stamped parts made of aluminum alloys are lightweight and corrosion-resistant, commonly used in automotive and electronic products; while steel stamped parts have higher strength, widely applied in heavy machinery and construction. The diversity of materials for OEM metal stamping parts allows them to meet the special requirements of various products.

OEM Metal Stamping Parts: Adaptation to Complex Designs and Mass Production

With the continuous advancement of industrial design, OEM metal stamping parts can produce components with complex shapes and precise structures. Through precision molds and advanced equipment, the stamping process can achieve complex shapes and detailed designs, meeting the needs of various complex designs. Additionally, the stamping process is very suitable for large-scale mass production, capable of producing a large number of identical or similar components in a short time, catering to the demands of large-scale production, particularly in industries like automotive and home appliances.

OEM Metal Stamping Parts: Fast Delivery and Efficient Production

The production efficiency of OEM metal stamping parts is very high, especially after the mold design is completed, the production speed can be significantly increased. The stamping process can complete the production of a large number of components in a short time, shortening the production cycle. Therefore, OEM metal stamping parts are particularly suitable for projects that require fast delivery, helping companies improve response speed and market competitiveness.

In summary, OEM metal stamping parts, with their advantages of high precision, cost-effectiveness, material diversity, adaptability to complex designs, and efficient production, are widely used in multiple industries. Whether in automotive, electronics, home appliances, or other fields, OEM metal stamping parts can meet the requirements of various industries for product quality and production efficiency. If you are looking for a high-quality OEM metal stamping parts supplier, Orienson will provide professional custom services to ensure your design needs are met and help you enhance product competitiveness.

English

English