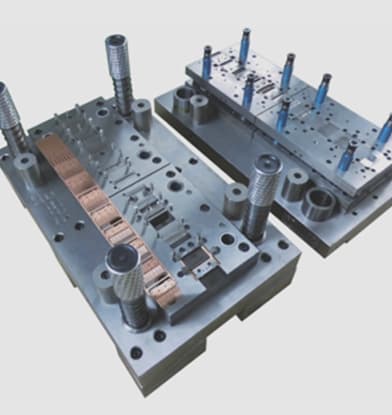

Utilizing Technology and Automation in Metal Stamping Parts Manufacturing

As one of the most crucial components in various industries, metal stamping parts are constantly in demand. From construction to automotive, metal stamping parts play a vital role in the production process. But with the ever-evolving manufacturing industry, it's important for companies to keep up with the latest technological advances. This is where the importance of technology and automation in metal stamping parts manufacturing comes into play.

Metal stamping parts manufacturer: The importance of technology and automation

In today's world, technology and automation have become the backbone of various industries. They enable businesses to operate more efficiently, increase productivity, and reduce turnaround times. In the metal stamping parts industry, technology and automation provide several benefits, including:

Increased accuracy and precision

Precision is key when it comes to metal stamping parts manufacturing. Even the slightest error can lead to costly mistakes and delays in production. By utilizing technology and automation, metal stamping parts manufacturers can ensure that all components are manufactured to exact specifications and tolerances.

Improved efficiency

Manual manufacturing processes are time-consuming and can be prone to human errors. By utilizing automation, metal stamping parts manufacturers can streamline the entire process to improve efficiency. Automation enables companies to produce high volumes of precise components quickly, reducing the overall turnaround time.

Cost-Effective

Automated systems reduce the need for manual labor, which can help metal stamping parts manufacturers save on labor costs. Automation also enables companies to produce large quantities of components at a faster rate, which can lead to increased profits.

How metal stamping parts manufacturers can implement technology and automation?

Implementing technology and automation in metal stamping parts manufacturing doesn't have to be overwhelming. Here are three steps that manufacturers can take to introduce these advancements into their processes:

Conduct a needs assessment

Before implementing any technology or automation systems, metal stamping parts manufacturers should conduct a needs assessment. This will help to identify areas where technology can help streamline the manufacturing process. It will also help to identify any potential issues or barriers to implementing automation.

Identify the right technology and automation systems

Once metal stamping parts manufacturers have assessed their needs, they can begin to evaluate the technology and automation systems available. It's important to choose systems that are compatible with existing equipment and processes to ensure a seamless transition.

Train employees

Finally, metal stamping parts manufacturers will need to provide comprehensive training to their employees on the new technology and automation systems. This will help to ensure that everyone is familiar with the equipment and can operate it safely and efficiently.

Technology and automation are critical components of modern manufacturing processes, including metal stamping parts manufacturing. Metal stamping parts manufacturers who adopt these advancements in their processes can improve precision, efficiency, and reduce costs. By following the steps outlined above, metal stamping parts manufacturers can successfully implement technology and automation systems, enhancing their operations and meeting the demand of their customers. As a metal stamping parts manufacturer, it's vital to prioritize the implementation of technology and automation in order to remain competitive and meet the expectations of the industries we serve.

English

English