Bending Parts

Edge Rolling Parts

Fine Blanking Parts

Deep Drawing Parts

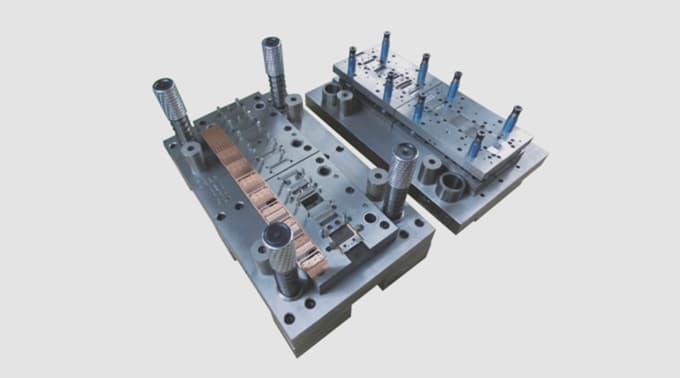

Copper Stamping

Stainless Steel Stamping

Steel Stamping

Aluminum Stamping

Assembling Service

CNC Machining

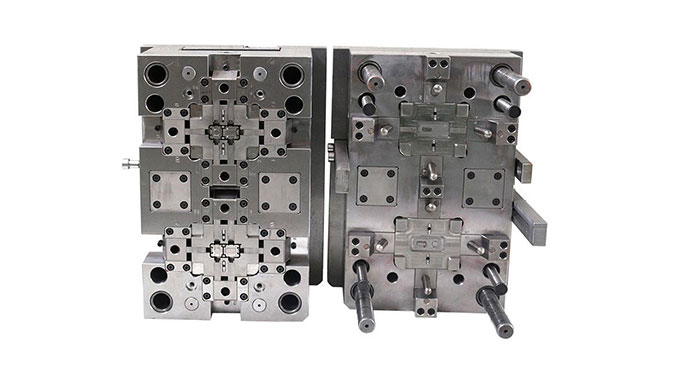

Plastic Injection Molding

Electroplating

Other Surface Treatment

Automatic Tapping

Automatic Riveting

Aerospace

Automotive

Electrical And Electronic Accessory

Optical Fiber Communication

Medical Device

Energy Development

Search

English

English