Precision Stamping Technology: Advantages and Applications

Precision stamping technology is an advanced manufacturing process developed from conventional stamping processes. By enhancing the guiding accuracy of presses and molds, reducing the fitting clearance of punches and dies, increasing reverse ejection pressure and V-ring hold-down pressure, and other process measures, precision stamping is achieved under intense triaxial compressive stress conditions. Alternatively, combining precision stamping with other composite forming processes can yield more accurate and less rough parts compared to conventional stamping. This article will delve into the advantages of Orienson's precision stamping technology, showcasing its applications and value in modern industrial production.

High part quality

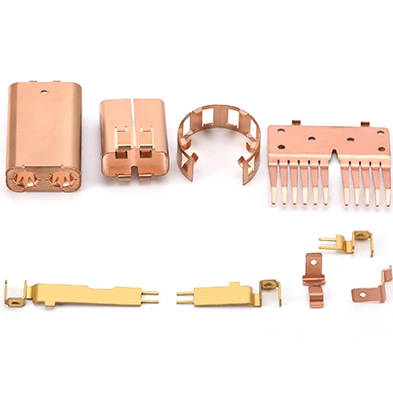

Compared to conventional stamping, precision stamping significantly improves the guiding accuracy of presses and molds, the manufacturing precision of molds, and reduces the fitting clearance of punches and dies. Especially when stamping under triaxial compressive stress with the lubrication and cooling aid of precision stamping oil, the dimensional accuracy and surface roughness of the sheared cross-section are greatly enhanced. This results in parts with exceptionally high quality, meeting the demands for high precision and high quality in production. Orienson, as one of the professional fine blanking parts manufacturers, focuses on custom precision metal stamped parts, with its terminals, connectors, contacts, and other metal stamping parts widely used in automotive, aerospace, and other fields, thanks to the high-quality parts produced by precision stamping technology.

Good part consistency

Precision stamping molds use special mold materials and heat treatment processes, resulting in high dimensional accuracy and a lifespan that is tens of times longer than that of conventional stamping molds. Therefore, the dimensional accuracy, shape, and positional accuracy of the produced parts are highly consistent, improving parts interchangeability, reducing the need for measurement and selection during assembly, and ensuring product consistency. Orienson leverages advanced mold design and manufacturing technologies to ensure the high precision and long lifespan of precision stamping molds, thereby providing customers with highly consistent precision parts.

High production efficiency

Compared to conventional stamping, precision stamping increases the dimensional precision, shape, and positional accuracy of parts, reduces the need for subsequent finishing operations, saves processing time on other equipment, reduces the number of intermediate product turnovers, and significantly shortens the manufacturing cycle and capital occupation of parts. This greatly enhances the overall economic efficiency of enterprises. By implementing precision stamping technology, Orienson achieves efficient production, quickly responds to customer needs, and provides short lead-time, high-quality precision parts.

High degree of automation

Precision stamping incorporates technologies such as high-precision stamping molds and intelligent control technologies, supplemented by stamping automation technology, which significantly reduces dependence on personnel. This not only improves working conditions and reduces costs but also ensures personal safety during stamping production. Orienson, as one of the professional fine blanking parts manufacturers with advanced stamping and testing equipment, integrates high-precision stamping mold technology and intelligent control technologies, greatly increasing the level of automation in the production process, further enhancing production efficiency and product quality.

Good overall benefits

Precision stamping technology has shown excellent application results in real-world production. High-speed precision stamping technology for mass production not only has the advantages of high product quality, good consistency, and high production efficiency but also saves labor, reduces energy consumption, shortens manufacturing cycles, and reduces capital occupation with the aid of stamping automation. This improves the economic efficiency of enterprises, making precision stamping technology increasingly accepted and recognized by companies. Orienson stands out in the competitive market by leveraging its advanced precision stamping technology and one-stop R&D services.

In summary, precision stamping technology holds a significant position in modern industrial production due to its outstanding advantages. Orienson, as one of the professional fine blanking parts manufacturers, uses precision stamping technology to provide customers with high-quality, consistent, and highly efficient precision parts. In future developments, with continuous technological advancements and the expansion of application fields, precision stamping technology will continue to play an essential role in modern industrial production, contributing more to the development of various industries.

English

English