High-Stakes Engineering: How Deep Drawing Suppliers Ensure Aerospace Quality

When it comes to the aerospace industry, quality and precision are of utmost importance. Every component and part must meet strict requirements to ensure the safety and efficiency of aircraft. One such critical process in aerospace engineering is deep drawing, which involves transforming a flat sheet of metal into a three-dimensional shape through the use of force.

Deep drawing suppliers play a crucial role in the aerospace industry by providing high-quality components that meet the complex specifications required for aircraft. In this blog, we will explore the role of deep drawing suppliers in ensuring aerospace quality.

The Importance of Deep Drawing in Aerospace Engineering

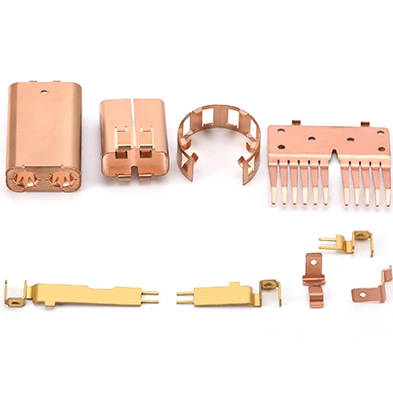

Deep drawing is a widely used manufacturing process in the aerospace industry due to its ability to produce complex, lightweight, and durable components. From engine components to structural parts, deep drawing plays a vital role in the production of aerospace machinery. The accuracy and precision achieved through deep drawing ensure consistent performance and reliability in highly demanding aerospace applications.

Meeting Stringent Industry Standards

The aerospace industry operates under stringent quality standards and certifications. Deep drawing suppliers must adhere to these standards to ensure that the components they produce meet the specific requirements of aerospace applications. From material selection to dimensional accuracy, deep drawing suppliers employ advanced techniques and technologies to meet the strict tolerances and specifications set by the industry.

Advanced Manufacturing Techniques

Deep drawing suppliers utilize advanced manufacturing techniques to ensure the highest levels of quality and precision. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software enable suppliers to design and simulate the deep drawing process before manufacturing begins. This allows for optimal material usage, minimizing waste and reducing overall production time.

Additionally, deep drawing suppliers invest in state-of-the-art machinery and equipment, including hydraulic and mechanical presses, to achieve the desired shapes and dimensions. These machines are capable of exerting significant force on the metal sheet to create complex aerospace components with exceptional accuracy and repeatability.

Collaboration and Expertise

Deep drawing suppliers work closely with aerospace engineers and designers to understand the specific requirements of each component and ensure that the deep drawing process meets these requirements. Collaboration between engineers and suppliers enables the optimization of designs for manufacturability, resulting in enhanced component performance and reduced production costs.

The expertise of deep drawing suppliers in material selection, tooling design, and process optimization is crucial in achieving aerospace quality. Through their understanding of the unique challenges and demands of the aerospace industry, deep drawing suppliers can recommend the most suitable materials and techniques to meet the highest standards.

Deep drawing suppliers play a vital role in ensuring aerospace quality by providing high-quality, precision-engineered components that meet the demanding requirements of the industry. With their advanced manufacturing techniques, adherence to stringent standards, and collaboration with aerospace engineers, deep drawing suppliers contribute to the overall safety and reliability of aircraft.

Orienson, a leading deep drawing supplier, is committed to providing aerospace-quality components through their expertise, state-of-the-art equipment, and collaboration with industry professionals. With their unwavering dedication to excellence, Orienson continues to support the aerospace industry's high-stakes engineering endeavors.

English

English