Detailed Explanation of the Copper Stamping Process

The copper stamping process is a common processing method with simple process flow and high efficiency, meeting the production needs of copper parts of different shapes and sizes. This article will detail the steps and process of copper stamping, so that you can understand the processing methods and precautions of the copper stamping process.

Steps of Copper Stamping Process

Raw Material Processing

The first step in the copper stamping process is to process the raw materials to make copper plates that meet the requirements. The processing includes stretching and drawing to ensure the quality and toughness of the copper material.

Material Selection

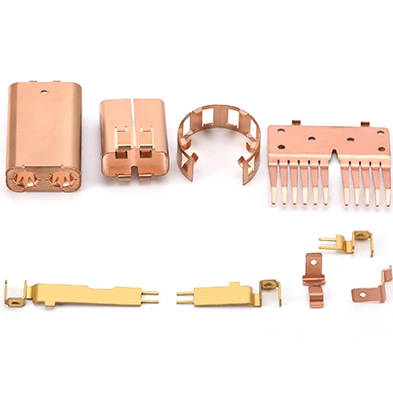

Material selection is an important part of the copper stamping process. Choosing the right material can improve the strength and corrosion resistance of the copper parts. Commonly used copper plates include red copper, brass, etc., with different materials selected according to different requirements.

Mold Design

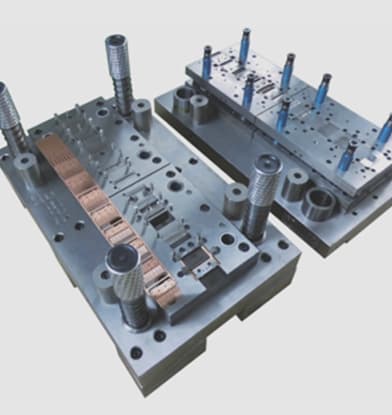

Mold design is the key to copper stamping processing. Different mold designs can produce copper parts of different shapes. The design needs to consider the shape, size, thickness, and other factors of the copper parts.

Stamping Processing

Stamping processing is the core step in the copper stamping process. It includes multiple steps such as hole making, trimming, and stamping forming. The quality of the stamping process directly affects the precision and quality of the copper parts.

Precautions in Copper Stamping Process

The mold must meet design requirements and not exceed its load capacity to avoid damage due to excessive pressure.

Before stamping, the copper plate surface needs to be cleaned to remove surface dirt and oxides, ensuring the surface smoothness of the copper parts.

During the stamping process, it is necessary to adjust the pressure and angle to ensure the precision and quality of the copper parts.

After stamping processing, the copper parts should be degreased, cleaned, etc., to ensure surface cleanliness and aesthetics.

Safety should be taken into account during copper parts processing to avoid accidents.

Copper stamping process has become an indispensable processing method in modern industry. Its process and steps are simple, and efficiency is high. With careful design and scientific process flow, high-quality and high-efficiency copper parts can be produced. Attention to safety and details is necessary during copper parts processing, and carelessness should be avoided.

Development Trends in Copper Stamping Process

High Precision and High Quality

With the continuous development of manufacturing, the requirements for copper stamping processing technology are getting higher. The stamping processing technology is also developing towards high precision and quality. By adopting more advanced materials and technology, more precise control of metal blanks can be achieved, producing more precise and higher quality parts and products.

Environmental Protection and Sustainable Development

With the increasing importance of environmental protection and sustainable development, copper stamping processing technology is also developing towards environmental protection and sustainable development. By using more environmentally friendly materials and processes, pollution and resource waste can be reduced, while also improving the sustainability and recyclability of products.

Personalization

With the diversification and personalization of consumer product demands, copper stamping technology is also developing towards personalization. By using more advanced computer technology and sensor technology, real-time monitoring and adjustment of metal blanks can be achieved, producing more personalized products.

English

English