Copper Stamping Parts from Orienson: A Model of Efficient Production and Quality Assurance

In the wave of manufacturing industry, copper stamping parts have become the key support for many industries with its excellent performance and wide range of applications. Orienson, with its outstanding technical strength and dedication to quality, provides customers around the world with efficient, high-quality copper stamping parts. Below, we will discuss in depth how Orienson has won wide acclaim in the market through efficient production and quality assurance.

Technology-driven to Realise Efficient Production

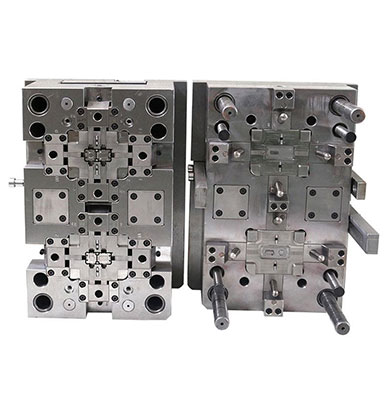

Orienson has always taken technological innovation as the core driving force for development. In the production process, the brand introduced advanced stamping equipment and automation technology, through the refined production process management, to achieve the efficient production of copper stamping parts. This not only significantly improves production efficiency, but also ensures product consistency and stability. At the same time, Orienson also focuses on staff skills training and quality improvement, to ensure that every employee can master the advanced production technology and operating standards, to provide a strong guarantee for efficient production.

Strict Quality Control: Casting Excellent Quality

Quality is the lifeline of Orienson. In order to ensure the excellent quality of copper stamping parts, the brand has established a strict quality management system. From the procurement of raw materials to the factory, every step of the product has been strictly inspected and tested. The brand has established long-term and stable relationships with high-quality suppliers to ensure the quality and stability of raw materials. Meanwhile, the brand also introduces advanced testing equipment and technical means to comprehensively test the performance indexes of copper stamping parts to ensure that the products meet customers' requirements and standards.

In addition, Orienson also focuses on the detailed management of the production process. During the production process, the brand implements strict process control and quality monitoring to ensure that each production link meets the standards. At the same time, the brand has also established a perfect quality traceability system, once found that the product problems, can be quickly traced back to the source of the problem and make improvements to ensure the continued stability of product quality.

Customer Demand-oriented to Provide Customised Services

Orienson knows that customer demand is the starting point and landing point of production. Therefore, the brand always adhere to the customer demand-oriented, to provide customers with customised copper stamping parts. With a professional technical team and rich production experience, the brand is able to provide quick response and precise design according to the specific needs of customers. Whether it is the size, shape or performance requirements of the product, Orienson can provide customers with satisfactory solutions.

Global Layout: Serving Global Customers

With the deep development of globalisation, Orienson is actively expanding the international market to provide customers around the world with high-quality copper stamping parts. The brand has established a perfect sales network and after-sales service system worldwide to ensure that customers can obtain products and services in a timely manner. At the same time, the brand also actively participates in international exhibitions and exchange activities, and establishes closer cooperation with global customers to jointly promote the development of the manufacturing industry.

All in all, Orienson provides high quality copper stamping parts to global customers by virtue of its advantages of efficient production, strict quality control, customer demand orientation and global layout. In the future, the brand will continue to uphold the "quality first, customer first" business philosophy, continuous innovation and progress, and contribute to the development of the global manufacturing industry.

English

English