Application and Development of Precision Stamping Technology

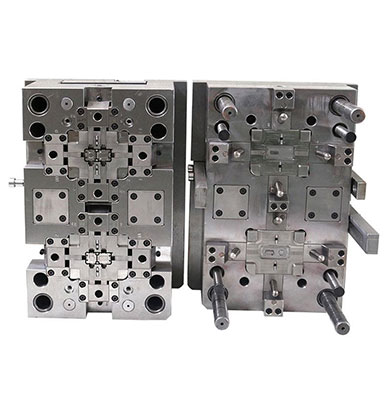

Precision stamping technology is playing an increasingly important role across various industries with its unique advantages. Some industries have organically integrated precision stamping with stamping automation technology, greatly enhancing stamping productivity and corporate efficiency. As products such as automobiles, electronics, communications, motors, electrical appliances, and home appliances rapidly become widespread, conventional stamping can no longer meet the high requirements of modern product manufacturing processes and technologies. Orienson is one of the specialized fine blanking parts manufacturers, focusing on customized precision metal stamping parts. Their terminals, connectors, contacts, fasteners, clips, cages, springs, brackets, and inserts are widely used in the automotive, aerospace, medical, fiber optics, and other fields.

Application Fields of Precision Stamping Technology

Application in the Automotive Industry

Against the backdrop of global energy conservation and emission reduction, automotive lightweighting has become an inevitable trend. With the rapid development of China's automotive industry and the continuous increase in market share of new energy vehicles, as well as the popularization of high-strength specialty steel that meets automotive lightweighting demands, precision stamping and forming technology is widely applied in structural and functional parts such as automotive engine systems, transmission and clutch systems, seat systems, and interior systems. Currently, the amount of precision-stamped steel used in Chinese passenger cars still lags behind developed countries. However, as precision stamping technology continues to mature and the costs of equipment and molds decrease, the amount of precision-stamped steel offered by Chinese fine blanking parts manufacturers is expected to approach or exceed the levels of developed countries, leading to broader application and development of precision stamping technology.

Application in the Motor Industry

The core of a motor is a crucial component, where its quality and consistency have a significant impact on the motor's performance. Currently, industries in China are using high-speed precision stamping technology in the production processes of silicon steel sheets and automatic stacking riveting, and silicon steel sheets with three-strand slotted torsion riveting. These technologies and equipment have reached the level of developed countries, strongly promoting the technological advancement of the motor industry in China.

Application in the Integrated Circuit Industry

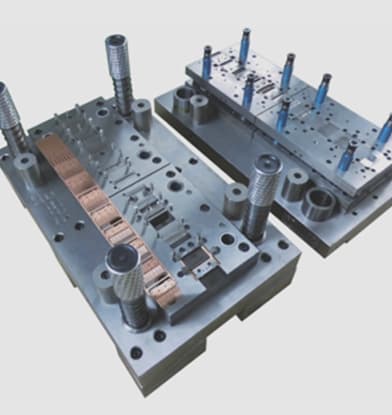

In integrated circuits, the application of precision stamping technology is more prevalent. As carriers of semiconductor chips, the manufacture of lead frames has strict requirements regarding precision, shape, and material thickness. Chinese fine blanking parts manufacturers use high-speed precision stamping technology to produce lead frames that meet these requirements, providing strong support for the development of the integrated circuit industry.

Development Trends in Precision Stamping Technology

With economic development and technological progress, precision stamping technology is advancing in multiple directions including precision, high-speed, flexibility, networking, integration, informationization, intelligence, low-carbon, environmental protection, and globalization.

Intelligence

With continuous advancements in science and technology, precision stamping equipment is gradually moving towards intelligence. Using advanced artificial intelligence and automatic measurement technologies, precision stamping equipment has gained high logical and judgment capabilities, enabling effective control and adjustment of precision stamping targets. This is an important development direction for the future of precision stamping technology.

Precision

Progress in modern technology is making products smaller in size, with higher requirements for dimensional and shape accuracy. This trend indicates that future products will demand higher precision, leading to a wider application of precision stamping technology in various fields.

Networking

The development of precision stamping technology and equipment requires integration with computer technology. As interconnection technology advances and many new control technologies mature, they need to be progressively applied in precision stamping equipment. Remote control technology, for example, has already reached a relatively mature stage.

Modularization

To adapt to product variability, precision stamping equipment must gradually achieve modularization. In developing new products, reasonable standards should be set, fully utilizing standard modules for product development.

For fine blanking parts manufacturers, the development of precision stamping technology brings unprecedented opportunities. As technology continues to advance and applications expand, the market demand for fine-stamped parts will keep growing. However, this also presents higher challenges for manufacturers. They need ongoing investment in research and development to enhance their technological capabilities to meet the rising market demand. Simultaneously, they must stay attuned to industry development trends, promptly adjusting production strategies to adapt to market changes. In this process, fine blanking parts manufacturers should closely collaborate with research institutions and universities to jointly promote the progress and application of precision stamping technology. Only through such measures can they remain competitive in the fierce market and become industry leaders.

English

English