Advantages of Copper Stamping Parts and Their Differences from Cast Parts

Advantages of Copper Stamping Parts

Excellent Electrical Conductivity

Copper is an excellent conductor, making it an ideal material for stamped electrical components. Copper stamping parts can withstand high currents and high voltages without overheating, making them perfect for applications requiring high conductivity.

High Thermal Conductivity

Copper's excellent thermal conductivity makes it an ideal material for stamped heat sinks and other thermal management components. Copper stamping parts can quickly dissipate heat, preventing equipment from overheating and improving overall performance.

Corrosion Resistance

As common OEM metal stamped parts, copper has strong corrosion resistance, making it an ideal material for outdoor and harsh environment applications. Copper stamping parts can withstand erosion from moisture and other corrosive elements without diminishing or losing their performance.

Excellent Formability

Copper has high ductility and toughness, making it easy to stamp into complex shapes. This allows the production of intricate parts and components with tight tolerances.

Cost-Effectiveness

Copper is an abundant material, relatively inexpensive compared to other metals, making copper stamping parts cost-effective for many applications.

Differences between Copper Stamping Parts and Cast Parts

Different Production Processes

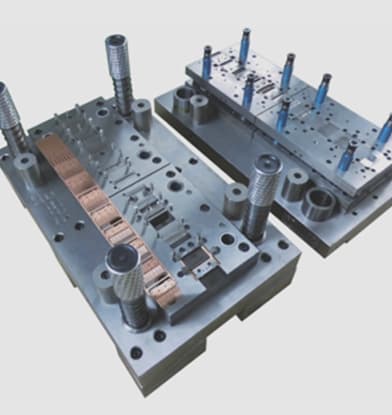

Copper stamping parts are produced by cutting, punching, bending, drawing, and other forming processes of copper sheets or coils in a die. This process is efficient and precise, especially suitable for mass production. Stamped parts typically have characteristics of being thin, uniform, light, and strong, meeting the requirements of modern industry for lightweight and high-strength components.

In contrast, the production process of copper cast parts involves pouring molten copper metal or alloy into a mold, which shapes after cooling and solidification. Casting can produce complex and large parts with a wide range of material choices. However, the casting process is relatively difficult to master and operate, and its production efficiency is relatively low.

Differences in Product Characteristics

Due to the use of mold forming, stamped parts have higher processing accuracy and good dimensional stability. The surface finish of stamped parts is also higher, requiring little post-processing to meet usage requirements. Additionally, copper stamping parts have good rigidity and strength, capable of withstanding high pressures and impacts.

Cast parts, on the other hand, generally have lower dimensional accuracy due to shrinkage and temperature changes during the cooling and solidification of the molten metal. The surface finish of cast parts is also not as good as that of stamped parts and may require additional machining or surface treatment to enhance performance.

Comparisons in Density

In terms of density, copper stamping parts usually exhibit higher density. This is because the stamping process can apply immense pressure to the metal sheet or coil, causing it to fit tightly against the mold surface, thus forming high-density parts. High density means stamped parts have better mechanical properties and corrosion resistance.

In contrast, cast parts have lower density. This is due to shrinkage holes, porosity, and other defects that easily occur during the cooling and solidification of the molten metal, affecting their density and mechanical properties. To improve the density of cast parts, a series of measures are typically taken, such as optimizing the casting process and using suitable risers and chills.

In summary, copper stamping parts have advantages in electrical and thermal conductivity, and corrosion resistance. They exhibit significant differences from cast parts in production processes, product characteristics, and density. The choice of production process for components should be based on specific application scenarios and requirements.

English

English